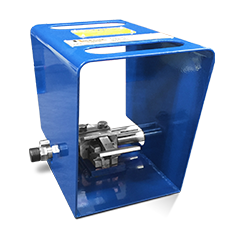

These flex lance guards consist of a set of stops, an inner diffuser and an outer handle. The flex lance is first threaded through the handle, and then the diffuser. A stop is then installed, and the inner diffuser is screwed into the outer handle. The operator can now grasp the handle and freely position the assembly in front of the tube that needs to be cleaned. The diffuser and handle ensures that the high pressure water cannot strike the operator’s hand, and the stop makes sure that the operator cannot pull the nozzle all the way out of the handle.

The LG-1525A and LG-1525B include stops for flex lances with O.D.’s of .320″ (8.1 mm), .450″ (11.4 mm) and .515″ (13.1 mm). The difference between the two is that the LG-1525A is designed to work on tubes with a minimum I.D. of .81″ (20.6 mm) while the LG-1525B works on tubes with a minimum I.D. of 1.00″ (25.4 mm).

| Part Number | Minimum Tube I.D. | Stops Included for Nozzle O.D. | |

|---|---|---|---|

| LG-1525A | 0.81" (20.6 mm) | .320" (8.1 mm) .450" (11.4 mm) .515" (13.1 mm) | $1 Get a Quote |

| LG-1525B | 1.00" (25.4 mm) | .320" (8.1 mm) .450" (11.4 mm) .515" (13.1 mm) | $1 Get a Quote |

Related Products

foot controls

Foot controls provide a simple way to start and stop the flow of high pressure water

Foot controls provide a simple way to start and stop the flow of high pressure water

Flex lance

NLB stocks a wide range of flexible lances with operating pressures to 40,000 psi (2,800 bar)

NLB stocks a wide range of flexible lances with operating pressures to 40,000 psi (2,800 bar)

Social Media

TwitterFacebookYoutubeLinkedinInstagram