Hydrostatic Pressure Pipe Testing Equipment

Problem:

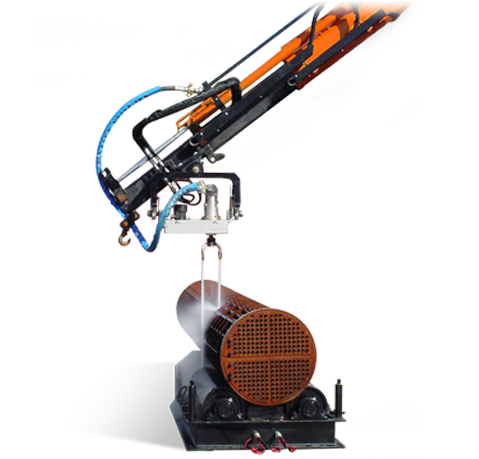

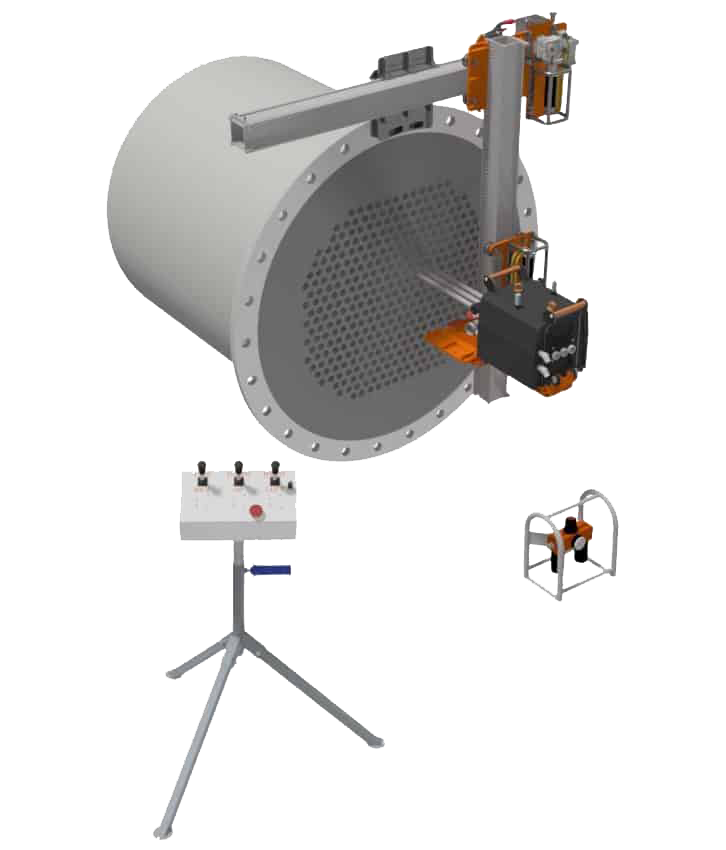

Heat exchanger systems lose efficiency when deposits build up in, and on, tube bundles. High-pressure water jetting cleans both I.D. and O.D. very effectively, but manual methods clean a limited area at a time and expose operators to strain and risk.

Solution:

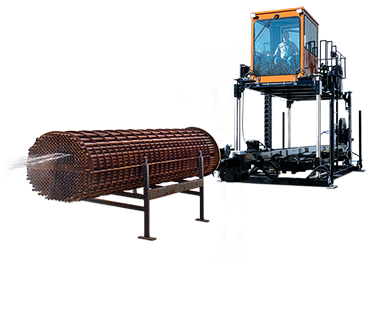

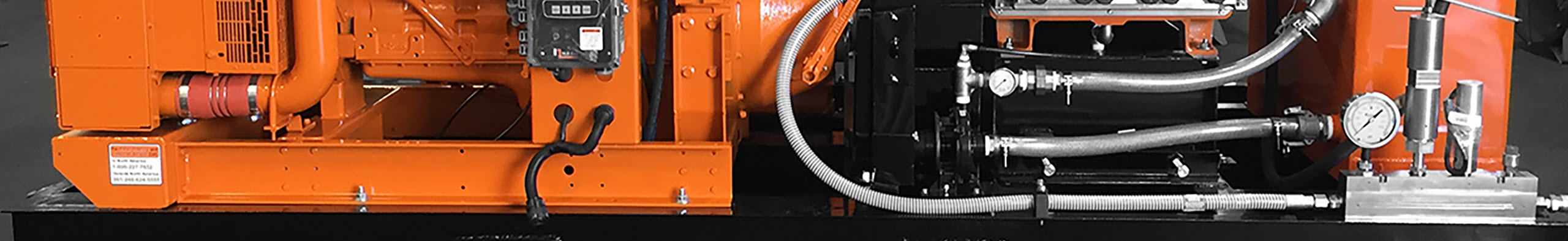

NLB has developed a number of efficient, automated, and semi-automated cleaning equipment solutions from the ATL-5022 bundle cleaning system for large bundles to the ShellJet™ exterior shellside cleaning options. For other applications, NLB has partnered with industry-leading tube/tube bundle cleaning equipment manufacturer Peinemann Equipment to provide customers with the most versatile, reliable, and innovative solutions.

Advantages:

- Less downtime (quickly back in action, longer between cleanings)

- Extremely thorough cleaning, inside and out

- Systems matched to user needs (pressure, flow, tube length)

- Very operator-friendly

To learn more about our hydrostatic pressure pipe testing equipment and tube bundle cleaning systems, contact NLB today.

Related Equipment

ATL-5022

Innovative design maintains high productivity for I.D. tube bundle cleaning, while lowering maintenance costs.

Innovative design maintains high productivity for I.D. tube bundle cleaning, while lowering maintenance costs.

Social Media

TwitterFacebookYoutubeLinkedinInstagram