Runway Rubber Removal Equipment

Dedicated Power. Longer Life.

There are a number of reasons to use a water jetting system from NLB for your next pavement marking or runway rubber removal project. As a leading StarJet Units provider, we have dedicated pages to tell you all about it. Learn how water jetting beats other systems. Runway rubber removal equipment can minimize substrate damage, reduce labor costs, create a stronger bond for new coatings, and eliminate the need for harmful chemicals. Find out why the StarJet Units system beats the competitor’s offerings.

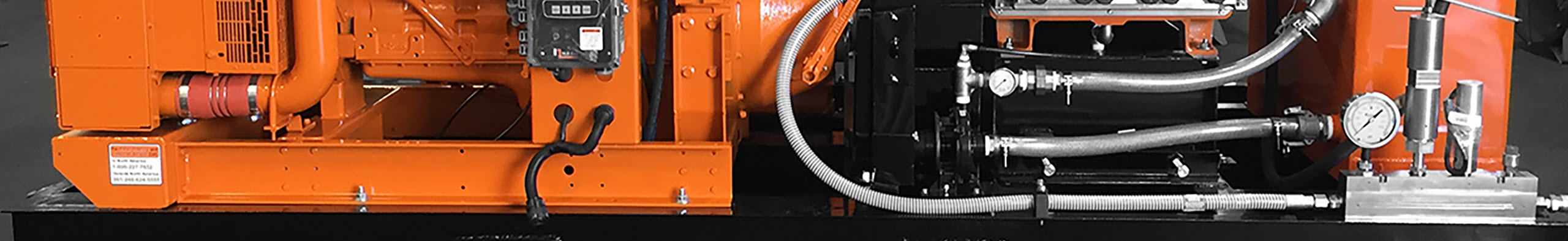

The dedicated pump engine means vastly improved production rates, and the ultra-high pressure water components have dramatically longer service lives. Become educated on the industry’s only pump replacement part guarantee. We’re so confident that our system is superior to the competition that we’ve put our money where our mouth is. See our industry-leading pump guarantee.

NLB custom-engineers complete StarJet systems to meet customer needs. Each incorporates all the UHP water jetting components (NLB rotating nozzle assembly and pump unit, water tank, and vacuum system) on a heavy-duty truck. The nozzles are mounted to the front of the truck and operated from the cabin. Key specifications are shown here, with some typical configurations. The driver hydraulically raises and lowers the nozzle assembly, which can be positioned to the left or right of the cab. A video system on the nozzle assembly lets him monitor progress from inside the cab while keeping his attention on the road.

As the most experienced manufacturer of StarJet Units — and the only one who designs and builds everything in-house — NLB is your best source of water jet systems for pavement applications. Please contact us for further details and application advice.

Contact us today to learn more about our runway rubber removal equipment.

Maximize Coverage

Dual rotating heads maximize coverage, with 20-plus configurations that let you choose 8” to 24” paths for stripe removal and up to 27” for rubber removal.

Simplify maintenance

Maintenance is simplified throughout the system. Nozzle changes are easy, and an auto-service mode positions the head for easy access. The UHP pump features long-life packing (800 to 1,800 hrs.).

Robotic ARM operation

Robotic assembly positions heads (raise/lower/sweep/extend/retract/rotate/index) hydraulically and is operated from the cab or outside.

Control console

Ergonomic control console in the cab has a touch screen, joystick, and lighted switches. It includes adjustable skip line controls so the truck can rapidly advance between skips.

Ultra-Clean® pump

High-uptime Ultra-Clean® pump (up to 10 times higher than other pumps) consistently delivers 40,000 psi water with minimal parts wear and low operating cost.

Vacuum recovery

Vacuum recovery is simple and efficient to pick up water and debris. It is possible to run a full shift without having to dump the debris.

Monitoring

Real-time monitoring, front and rear, of removal area (and traffic) via high-resolution color video cameras. Features StarJet Assist tutorial that allows the operator to view onboard library videos based on system fault indicators.

| Model | Cleaning Paths | Head Rotation Speed | Water Jet Pump | Truck Details | Speed Control | Fresh Water Supply | Vacuum | Debris Tank | |

|---|---|---|---|---|---|---|---|---|---|

| SRV-7 | 10" to 28" | Up to 3,000 rpm (adjustable) | NLB 325, rated to 40,000 psi (2,800 bar) @ 13 gpm | 80,000 GVR with tandem axle chassis, 350 hp engine & 6-speed automatic transmission | 0 - 350 fpm with hydrostatic creep drive | 2,100 gallons (7,949 l) | 1,500 cfm, @ 3' - 5' | 1,700 gallons of water and debris (6,435 l) |

| SRV-6 | 10" to 27" | Up to 3,000 rpm (adjustable) | NLB 325, rated to 40,000 psi (2,800 bar) @ 16 gpm | 80,000 GVR with tandem axle chassis, 450 hp engine & 6-speed automatic transmission | 0 - 350 fpm with hydrostatic creep drive | 3,000 gallons (11,356 l) | 1,500 cfm, @ 3' - 5' | 6 cubic yards of debris, and 3,000 gallons of water (4.6 cubic meters, 11,356 l) |

| SRV-4 | 10" to 27" | Up to 3,000 rpm (adjustable) | NLB 325, rated to 40,000 psi (2,800 bar) @ 13 gpm | 80,000 GVR with tandem axle chassis, 350 hp engine & 6-speed automatic transmission | 0 - 350 fpm with hydrostatic creep drive | 2,200 gallons (8,328 l) | 1,500 cfm, @ 3' - 5' | 4 cubic yards of debris, and 950 gallons of water (3 cubic meters, 3,596 l) |

| SRV-4S | 10" to 27" | Up to 3,000 rpm (adjustable) | NLB 325, rated to 40,000 psi (2,800 bar) @ 13 gpm | 80,000 GVR with tandem axle chassis, 350 hp engine & 6-speed automatic transmission | 0 - 350 fpm with hydrostatic creep drive | 2,200 gallons (8,328 l) | 1,500 cfm, @ 3' - 5' | 4 cubic yards of debris and 950 gallons of water (3 cubic meters, 3,596 l) |

| SRV-1 | 10" to 14" | Up to 3,000 rpm | NLB 40225, rated to 40,000 psi (2,800 bar) @ 10 gpm | 52,000 GVRW with tandem axle chassis, 300 hp engine & 6-speed automatic transmission | 0 - 400 fpm with hydrostatic creep drive | 1,000 gallons (3,785 l) | 1,000 cfm | 1,000 gallons of water and debris (3,785 l) |

| SRV-1S | 10" to 14" | Up to 3,000 rpm | NLB 40225, rated to 40,000 psi (2,800 bar) @ 10 gpm | 52,000 GVRW with tandem axle chassis, 300 hp engine & 6-speed automatic transmission | 0 - 400 fpm with hydrostatic creep drive | 1,000 gallons (3,785 l) | 1,000 cfm | 1,000 gallons of water and debris (3,785 l) |

Looking for a Skid-Mounted unit?

Fluid End Part Guarantee

1-Year (Standard) or 7 years

NLB high-pressure pumps set the industry standard for their rugged reliability, and now you can put that reliability to work for your pavement marking or rubber removal project. In fact, we are so sure that our pump will perform day-in and day-out without any maintenance that we have created the industry’s only fluid end pump guarantee. Your StarJet® truck will not require a single pump replacement part, in the fluid end, during its first year of service. If it does, send the part back to us and we will provide a replacement part for free*.

Or take it to the next level. Purchase our 7-year pump maintenance package and we guarantee you will not have another fluid end related cost over the truck’s first seven years of operation. You receive a complete set of spare cartridge assemblies for your pump. If you experience any issues, simply replace the faulty cartridge assemblies with the spare set, and ship the faulty ones back to NLB. We will completely refurbish the components and quickly return them to you for future use.

Find the peace of mind that other truck operators have found when switching to the StarJet®. Unparalleled productivity and reliability, all backed by the only pump cost guarantee available.

*NLB will replace any fluid end pump component that fails at no charge if the procedures in NLB’s operation manual have been followed. NLB will not be responsible for labor, freight or consequential damage.

Related Accessories

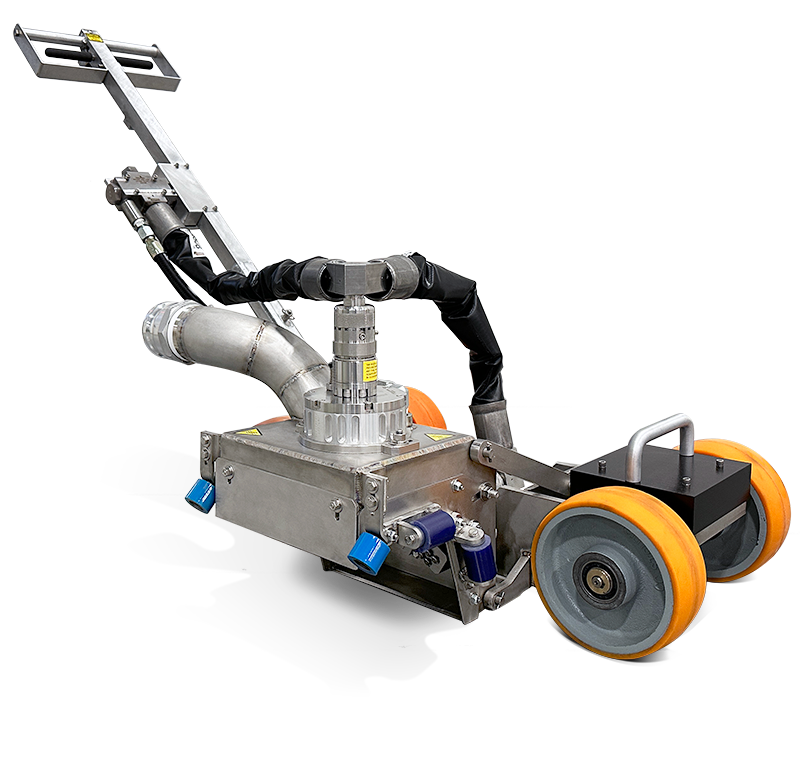

Curb Cleaner

Our newest high-pressure water jetting accessory can adjust to clean a wide range of curb profiles

Our newest high-pressure water jetting accessory can adjust to clean a wide range of curb profiles

![]()

Looking for Parts and Service?

NLB keeps on hand a substantial inventory of top-quality spare parts for StarJet trucks and NLB pump units, ready for immediate delivery.

Social Media

TwitterFacebookYoutubeLinkedinInstagram