Water Jetting Questions

Q: Who purchases and uses these type of machines?

Water jet units are used by many types of industries and by contractors who provide specialty-cleaning services to those industries. They are also widely used by the surface prep industry to remove all sorts of paints and coatings. Essentially, if you have a product that is extremely difficult to remove, water jets could be your answer. Here is a small sampling of specialized applications:

- Paint Shops: Water jets are the single most effective tool for removing both live and cured paint from fixtures, carriers, and grates. Almost every automotive paint shop in the world has a high-pressure water jetting system in place.

- Cutting: Water jets are used around the world to cut all types of materials. There are basically two methods. Straight water jet cutting uses only water and is typically used for softer materials, like food, cloth, foam, or wood. Abrasive water jet cutting mixes an abrasive into the water to cut even the hardest metals.

- Energy Production: Water jets are used extensively by power plants to clean boilers, re-heaters, cyclones, and scrubbers.

- Chemical and Plastic Plants: Water jets are used for tank and reactor cleaning, and for pipe and tube cleaning.

Q: With all that pressure, how can you even hold onto the lance?

NLB carefully designs equipment to fit operators’ needs. Our hand lances, for example, have shoulder stocks and other ergonomic features that make them comfortable to operate. If you have questions about how much water a person can handle at any specific pressure, please contact us.

Q: How much do high-pressure water jet systems cost?

Costs vary with your needs. If you can tell us about your application, we’ll be happy to help determine exactly what type of equipment you need, and its cost.

Q: How far should the nozzle be from the material I am trying to remove?

The distance between the nozzle and surface is directly related to the volume of water you have to work with. Typically, the more water you have, the further away you can work.

As a frame of reference, NLB tank cleaning systems typically use as much as 50 gallons (189 lpm) per minute and can reach out nearly 15 feet (4.6 m). Conversely, our ultra-high pressure systems might only use 3 gallons (11 lpm) per minute and could discharge that flow out over 8 or more nozzles. In this type of an application, you would need to be only a few inches from the surface you are trying to clean.

Q: Can I run multiple tools at once?

Yes. NLB has a multi-gun valve that allows two or more people to work off the same pump. This valve allows each operator to start and stop the flow of water to his or her lance without affecting the other operators.

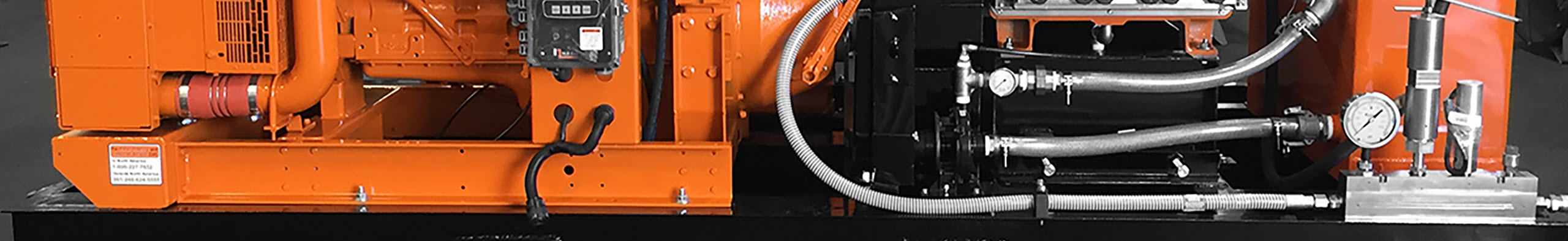

Q: What size pump is best?

This depends on the kind of work you want to do. If you know how much water you’ll be using, and what pressure you need, you can look over the different models we offer and select the correct one. If not, please contact us. We have years of experience in helping people select the best pump for their application.

Note: When considering horsepower, please be sure to look at hydraulic horsepower, not the horsepower of the engine or motor running the pump. The ‘Pump Horsepower’ in many companies’ marketing literature refers to the horsepower driving the pump, not the actual horsepower that makes it to your nozzle. These are NOT the same thing. NLB can explain this in detail and can provide formulas to calculate how much horsepower you can actually expect.

Q: How important is pressure? Is maximum pressure always better?

No. Pressure and Flow both play key roles in an efficient water jetting system, and applications respond differently to each variable. Typically, hardened deposits respond better to higher pressures, and softer materials are best removed with higher flows. Each application is unique, though, and NLB can help you determine which combination of pressure and flow will work best for you.

Q: With all that pressure, are water jets safe?

Water jets are less dangerous than many other methods. Nevertheless, proper safety procedures must be followed, and they require the same respect that you would afford any power tool.

Social Media

TwitterFacebookYoutubeLinkedinInstagram