Problem:

Ceramic shells are typically chipped away from investment castings, a process that is not only tedious and labor-intensive but can damage the casting inside. The more intricate the casting shape for the application, the bigger the problem.

Solution:

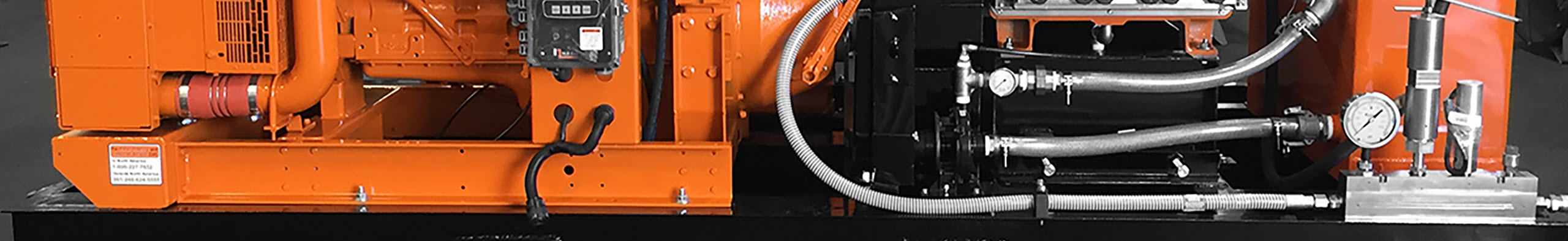

NLB high-pressure casting removal water jetting system cuts cleanly through the hard ceramic but leaves the casting unscathed. Typically, precision nozzles are mounted on a robotic arm or hand lance, providing more thorough coverage and significantly higher productivity.

Casting Removal Water Jetting Advantages:

- Complete shell removal in minutes

- No damage to valuable castings

- Can be manual or automated

- Easier on personnel

- Standard cabinets available

More Info

Product application bulletin

Read about a customer’s own experience using water jets to remove investment castings

Read about a customer’s own experience using water jets to remove investment castings

Social Media

TwitterFacebookYoutubeLinkedinInstagram