Same legendary performance.

More technological advancements.

NLB removal systems own the highest production removal rates in the industry. Now, the new SRV-6 offers even more and resets the bar on stripe removal production rates. We’re not rolling out a tweaked version of our previous model, but instead, have looked at all the key product operational elements that affect unit productivity. Changes to the head design and components, the engines, the front end operator flexibility and truck weight balance. These improvements, when combined, add up to higher production numbers for you and more profitability in the process.

If you’re looking for the newest most advanced rubber and stripe removal system available, look to the NLB SRV-6.

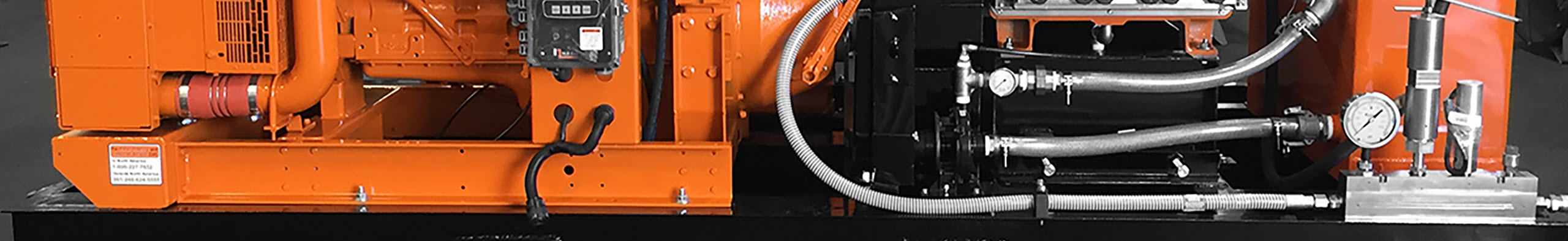

More Dedicated Horsepower

We’ve always engineered our Starjet units to work off of two engines – dedicated power for the truck and a dedicated engine for the pump. Why? Because there’s no value in a truck with a life that runs out long before it’s paid for itself. We’ve also added more power to the SRV-6, offering a 450 HP engine solely for the water jetting pump and a 350 HP engine to keep powering the truck down the road long after the competitions have failed. That also means more consistent water pressure flow when going up hills or putting extra demands on the truck engine.

More Head Control

New with the SRV-6 is a two-head SpinJet bucket design, each head can be operated independently and run at different speeds. Head positioning options allow for maximizing surface cleaning area coverage to meet project removal requirements. We didn’t just have the operator in mind when designing this system. The SRV-6 heads are easier to access for belt changes and other routine maintenance. The new design allows for conversions to larger SpinJet bars for specific applications.

More Flexibility

NLB’s new indexing front head carriage provides nearly infinite bucket head locations with side-to-side movement all controlled comfortably from the cab with easy controls and sight lines. This movement makes the removal of stop bars, arrows and other challenging painted surfaces much easier without all of the back-and-forth movements operators may have experienced in the past. The carriage also offers higher curb clearance for entering and exiting roadways and other uneven pavement areas. Lastly, the design dramatically improves front-end balance while in transportation mode, reducing wear on front-end chassis suspension systems.

More Balance

NLB engineers took the challenge of improved water/debris weight balance head on. By redesigning the truck’s back-end tank and axle configurations to handle the shifts in fresh water reductions and debris collection the axle load does not change during operation. The result is longer operation between water refills and debris removal.

| Features and Specifications | |

|---|---|

| Cleaning Paths | 10" to 30.25" |

| Head Rotation Speed | Up to 3,000 rpm |

| Water Jet Pump | 40325H CV450-H |

| Truck Details | 80,000 GVR with tandem axle chassis, 450 HP engine & 6-speed automatic transmission |

| Speed Control | 0-350 fpm with hydrostatic creep drive |

| Fresh Water Supply | 3,000 gallons (11,356 l) |

| Vacuum | 1,500 cfm, @ 3' - 5' |

| Debris Tank | 6 cubic yards of debris, and 1,732 gallons of water (4.6 cubic meters, 6,556 l) |

$1 Get a Quote

Troubleshooting & Solutions

StarJet® ASSIST system is an integrated troubleshooting tool that offers video tutorials through the truck’s onboard display screen. These videos are made available here on our website as well.

Social Media

TwitterFacebookYoutubeLinkedinInstagram