Technology & Design Centered on Performance.

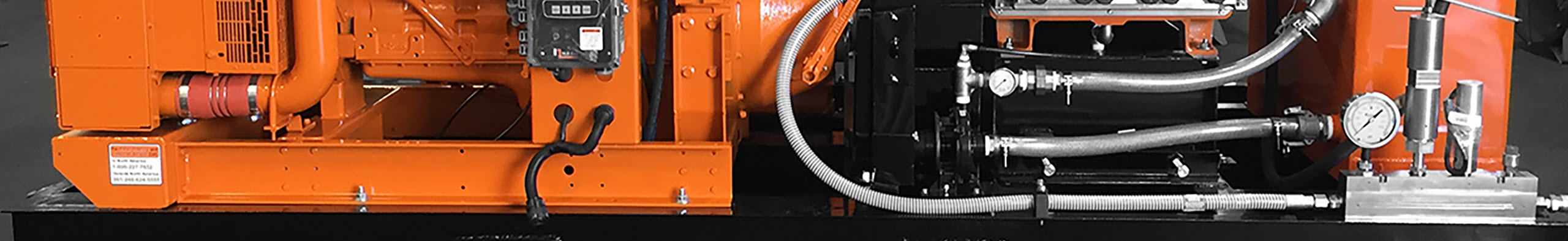

NLB StarJet ultra high-pressure water jetting stripe removal systems have held a position as the most durable, technology performance production leaders in the industry. The SRV-7 builds on that heritage by introducing a new center-component design that offers improved performance, less wear and reduced maintenance.

The key to this new design is the concept of balance. The slow-running, robust 325 Series pump, along with a Cummins (L9-430 T4F Stage V) 430 hp diesel engine are in centerline position on the chassis, resulting in a more even chassis weight distribution. Add that to the unique water/debris collection design that proportionately distributes fresh water and collected debris, and you eliminate uneven weight transfer from job start to finish.

The SRV-7 also features NLB’s innovative E-Clutch™ technology that allows for the elimination of the PTO while reducing component wear on the power plant.

Other benefits to this design; reduced chassis wiring, and fewer high-pressure hoses and electrical components. A new, lighter weight side-to-side movement front-end arm adds to the high-performance removal capabilities.

High-Pressure Pump

- Pumping system generates 13 gpm (49.2 lpm) at 40,000

psi (2,800 bar).

SRV-7 Features Include

- Hydraulically actuated removal assembly with proportional controls.

- Long life UHP seal assemblies with simple to replace seal for ease of maintenance.

- Fully automatic front end service mode makes maintenance and nozzle changes quick and easy.

- Dual heads for maximum productivity. Multiple nozzle bar assemblies available to match any application.

- High resolution touch screen operator interface with adjustable skip line controls allow the operator to advance between skips.

- Hydrostatic creep drive for precise speed control during removal (0-350 fpm).

- Slow running plunger pump built from high-grade stainless steel and provides unprecedented reliability.

- High powered on-board vac unit provides 1,500 CFM.

NLB engineers took the challenge of improved water/debris weight balance head on. By redesigning the truck’s back-end tank and axle configurations to handle the shifts in fresh water reductions and debris collection the axle load does not change during operation. The result is longer operation between water refills and debris removal.

NLB’s new indexing front head carriage traverses side-to-side for automated removal of stop bars.

The ergonomically designed control system puts everything at the drivers finger tips and is available in either single or dual steer configurations.

High resolution in-cab video monitor allows the operator to monitor progress as well as surrounding traffic.

| Features and Specifications | |

|---|---|

| Cleaning Paths | 10" to 28" |

| Head Rotation Speed | Up to 3,000 rpm (adjustable) |

| Water Jet Pump | NLB 325, rated to 40,000 psi (2,800 bar) |

| Truck Details | 80,000 GVR with pusher axle chassis, 430 HP engine & 6-speed automatic transmission |

| Speed Control | 0-350 fpm with hydrostatic creep drive |

| Fresh Water Supply | 2,200 gallons (8,328 l) |

| Vacuum | 1,500 cfm, @ 3' - 5' |

| Debris Tank | 5 cubic yards of debris, and 1,785 gallons of water (3.8 cubic meters, 6,757 l) |

Fluid End Part Guarantee

1-Year (Standard) or 7 years

NLB high-pressure pumps set the industry standard for their rugged reliability, and now you can put that reliability to work for your pavement marking or rubber removal project. In fact, we are so sure that our pump will perform day-in and day-out without any maintenance that we have created the industry’s only fluid end pump guarantee. Your StarJet® truck will not require a single pump replacement part, in the fluid end, during its first year of service. If it does, send the part back to us and we will provide a replacement part for free*.

Or take it to the next level. Purchase our 7-year pump maintenance package and we guarantee you will not have another fluid end related cost over the truck’s first five years of operation. You receive a complete set of spare cartridge assemblies for your pump. If you experience any issues, simply replace the faulty cartridge assemblies with the spare set, and ship the faulty ones back to NLB. We will completely refurbish the components and quickly return them to you for future use.

Find the peace of mind that other truck operators have found when switching to the StarJet®. Unparalleled productivity and reliability, all backed by the only pump cost guarantee available.

*NLB will replace any fluid end pump component that fails at no charge if the procedures in NLB’s operation manual have been followed. NLB will not be responsible for labor, freight or consequential damage.

$1 Get a Quote

![]()

Troubleshooting & Solutions

StarJet® ASSIST system is an integrated troubleshooting tool that offers video tutorials through the truck’s onboard display screen. These videos are made available here on our website as well.

Reviews

There are no reviews yet.