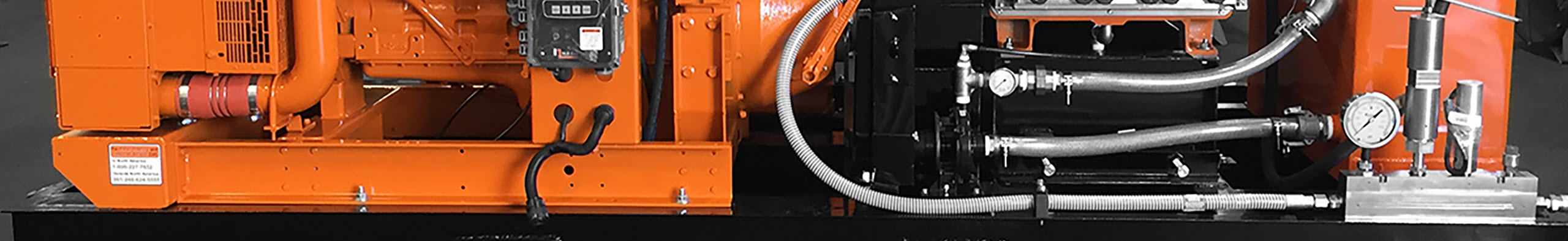

NLB’s newest water jetting unit is turning heads – and for good reason. The new NLB 175 Series brings all the features that users want and at a price that is less than one might think for NLB quality. Careful engine pairing and engineering help to generate more of what users need (namely pressure and flow), utilizing a smaller, higher output power frame. The result is a jetting unit with the performance needed in a smaller, lighter package. The 175 Series isn’t some stripped-down, quality-compromised effort on anyone’s part. It’s all the NLB quality and more that carries the NLB nameplate.

The units are built using the same rugged, reliable designs that have been field-proven for over 50 years. The trailer-mounted unit comes standard with features like four-wheel electronic brakes, a full D.O.T. lighting package, and heavy-duty axles.

Industrial Engine

Pumping system includes a continuous-duty four-cylinder diesel engine:

- Model 175: 175-200 hp (130-149 kw)

Trailer Mounting

- Heavy-duty tandem axle design

- 14″ wheels (355 mm)

- D.O.T. lighting package

- Heavy-duty fenders

- Electric brakes

- Industrial grade enamel paint

- Size: 79″ wide x 164″ long x 80″ high

Approx. (2.0 m wide x 4.2 m long x 2.3 m high) - Weight: 6,300 lbs. (2,858 kg) approx.

Unit Features

- Slow running plunger pump built from high-grade

stainless steel, provides unprecedented reliability - A single accessory manifold for 8K to 20K operation

with pressure gauge, rupture disc and by-pass valve - Throttle controls operator demand and adjusts output

- Lightweight and trailer-mounted for ease of mobility

Engine Driven Pumping Assembly

- Slow running NLB Model 175 reciprocating pump

- Standard three plunger water lubrication

- 90 gallon (341 l) fuel tank

- 12 electric start

- Inlet water filter

- 50,000 lb. glycerin-filled pressure gauge with snubber

- Accessory manifold with by-pass valve

- All necessary plumbing and operating controls

- Skid mounted option available

- Available engine mounted air compressor (up to 70 cfm)

E-Clutch™ +

The E-Clutch allows the operator to immediately stop the flow of high-pressure water by disengaging the pump from the engine. This completely eliminates the need for a dump valve — cutting cost, complexity, and risk to the operator. Only E-Clutch units can link wirelessly with Esync accessory tools (hand lance, foot control, pendant), for remote water jetting control, and incorporating the tools couldn’t be easier!

| Part Number | gpm | lpm | psi | bar | |

|---|---|---|---|---|---|

| Model 175 - 175-200 hp (130-149 kW) | |||||

| 40175D | 6.0 | 23.0 | 40,000 | 2,800 | $1 Get a Quote |

| 35175D | 7.2 | 27.0 | 35,000 | 2,450 | $1 Get a Quote |

| 20175D | 12.0 | 45.4 | 20,000 | 1,400 | $1 Get a Quote |

| 15175D | 15.3 | 57.9 | 15,000 | 1,000 | $1 Get a Quote |

| 10175D | 23.4 | 88.5 | 10,000 | 700 | $1 Get a Quote |

| 8175D | 28.9 | 109.5 | 8,000 | 550 | $1 Get a Quote |

Social Media

TwitterFacebookYoutubeLinkedinInstagram