I.D. Tube Bundle Cleaner

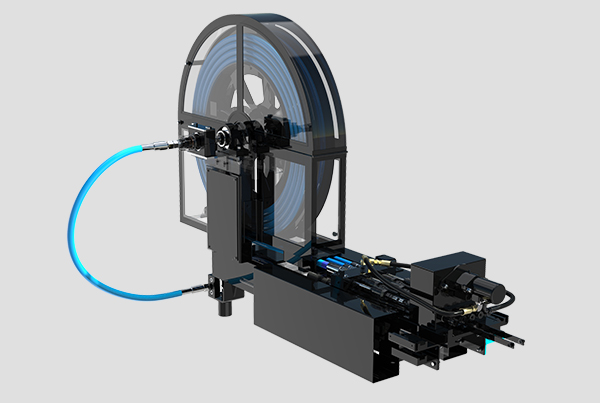

The ATL-5022 automated tube bundle cleaner delivers the productivity users loved in NLB’s ATL-5015 with new features to maximize uptime and reduce maintenance costs.

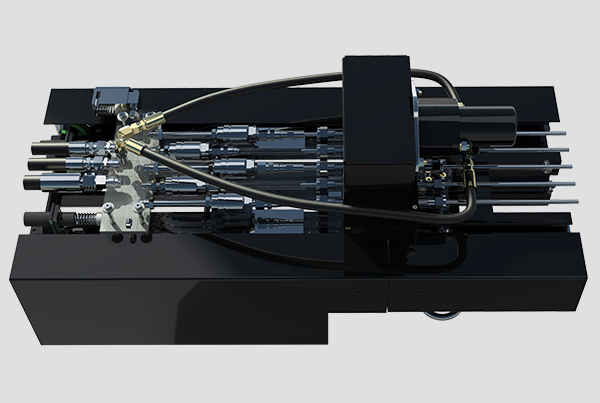

Like the earlier model, the ATL-5022 cleans five tubes at a time… but with rotating lances instead of rotating nozzles. This means less nozzle wear and makes it possible to use smaller pumps. And instead of five hoses for five lances, all five are fed by a single hose and a floating manifold — so there’s less chance of a hose getting tangled.

The operator directs all lance and outrigger/leveler movement from the same climate-controlled station as the previous version, with controls now conveniently consolidated in a single joystick. The touch-screen monitor and controls hardware are user-friendly, have fewer programs to maintain, and allow remote troubleshooting by the user or by NLB.

The ATL-5022 is a self-contained system that is three times as productive as manual bundle cleaning methods and built for years of trouble-free operation.

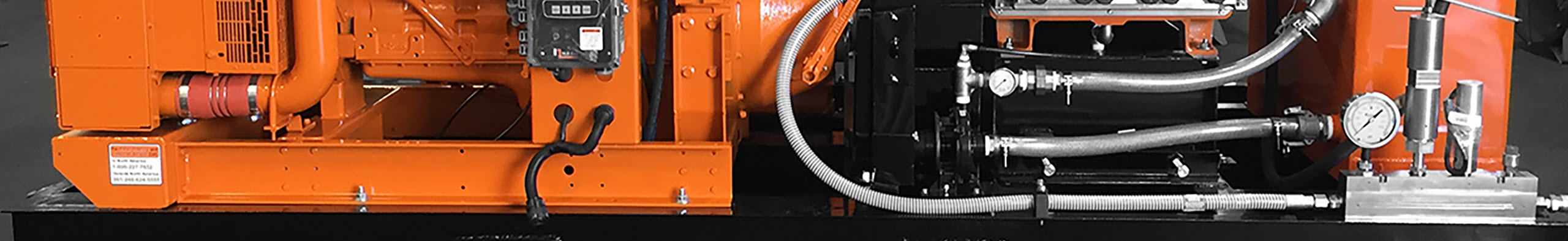

Industrial Engine:

- Cleaning system includes a 3-cylinder diesel engine rated for 25 hp (18 kw).

Unit Features:

- Completely self-sufficient system requiring no external power supply

- A standard HVAC package heats and cools the operator station as needed

- System can be operated at pressures to 20,000 psi (1,400 bar)

- Fully adjustable lance stroke length allows the machine to be configured for bundles of different lengths

- New ¾” I.D. single flex lance reduces pressure drop and prevents hose entanglement

- Cleaning horsepower is maximized, making cleaning more effective

- Lance containment system minimizes wear and promotes longer lance life

- Larger outrigger design comes standard and adds greater stability when extended

- Integrated lance storage for up to 10 rigid lances (34’ long)

- Optional hydraulically-driven 100,000 lb. capacity bundle roller set

- Remote diagnostics, provided by NLB, are available from any location where you receive cell service

Specifications:

- Weight: 12,000 lbs (5,448 kg) approx.

- Size (shipping): 462″ long x 101″ wide x 104″ high approx. (11.73 m x 2.56 m x 2.64 m)

- Lance speed: 39″ (1 m) per second

- Lance rotation speed: Variable, 500 rpm max.

- Max. cleaning width: 59″ (1.5 m)

- Lance bed vertical movement: 50″ (1.27 m)

- Max. lance height: 74″ (1.88 m)

- Min. lance height: 24″ (.6 m)

- Max. working pressure: 20,000 psi (1,400 bar)

- Lance pitch adjustment: .75″ (19.05 mm) to 1.94″ (49.28 mm)

- Rigid lance forward thrust: 0-250 lbs. per lance

- NLB V20-495 system valve

The lances rotate using a user-friendly chain drive that’s easy to maintain.

Simplifying from five flex lances to one, cuts down on replacement costs and avoids unexpected, costly downtime.

Rotating swivels keep nozzles in rotation while cutting back on wear.

| Model | Max. Pressure | Size (Shipping | Weight | Lance Speed | Lance Rotation Speed | Max. Cleaning Width | Lance Bed Vertical Movement | Max. Lance Height | Min. Lance Height | Lance Pitch Adjustment | Rigid Lance Forward Thrust | System Valve |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ATL-5022 | 20,000 psi (1,400 bar) | 462" long x 101" wide x 104" high approx. (11.73 m x 2.56 m x 2.64 m) | 12,000 lbs. (5,448 kg) approx. | 39" (1 m) per second | Variable, 500 rpm max. | 59″ (1.5 m) | 50" (1.27 m) | 74" (1.88 m) | 24" (0.6 m) | 0.75" (19.05 mm) to 1.94" (49.28 mm) | 0-250 lbs. per lance | NLB V20-495 |

$1 Get a Quote

Related Products

rigid lance

The ATL-5022 uses five sections of rigid lance to speed through pipe cleaning jobs

The ATL-5022 uses five sections of rigid lance to speed through pipe cleaning jobs

Social Media

TwitterFacebookYoutubeLinkedinInstagram